Basingstoke, Hampshire 23rd September 2025, CDG Replik8, a provider of on-demand industrial 3D scanning, additive manufacturing, and prototyping services, has been selected to create a lifelike crab-shaped serving dish in brass for luxury homeware design brand, Culinary Concepts.

The bespoke brass artifact was made on special commission for a London Mayfair restaurant to provide a unique experience for diners who order dressed crab from its menu.

Explaining how the manufacturing method allowed Culinary Concepts to meet its client’s tight deadline, Emma Jane B., creative designer at Culinary Concepts, said, “While our sculpting team is highly accomplished, the level of accuracy and tight deadline required for this project made us immediately think of CDG. How could we create a realistic crab dish on such a short timeline? By using a real crab and having it 3D scanned and printed!”

To achieve the lifelike appearance of the bronze crab serving dish, the Replik8 team used a FreeScan Combo+ infrared and laser 3D scanner to scan a frozen crab.

Morgan Chapon, Replik8 marketing manager, describes how the team achieved the required level of accuracy, “We did the first scan using the 90 laser line mode, to complete a quick data grab of the crab’s size and outline form. Then we switched to single laser line mode to capture the fine detail of the shell surface to 0.02mm accuracy.”

The team had to work quickly before the crab thawed and its claws changed position. They also had to align the back legs within the CAD software to ensure that the 3D printed prototype wouldn’t wobble.

Geomagic Design X, scan-to-CAD software was used to smooth the scanned surfaces. This also allowed the Replik8 team to create a container shape for the dressed crab servings, by cutting a hollow into the top part of the shell within the CAD software.

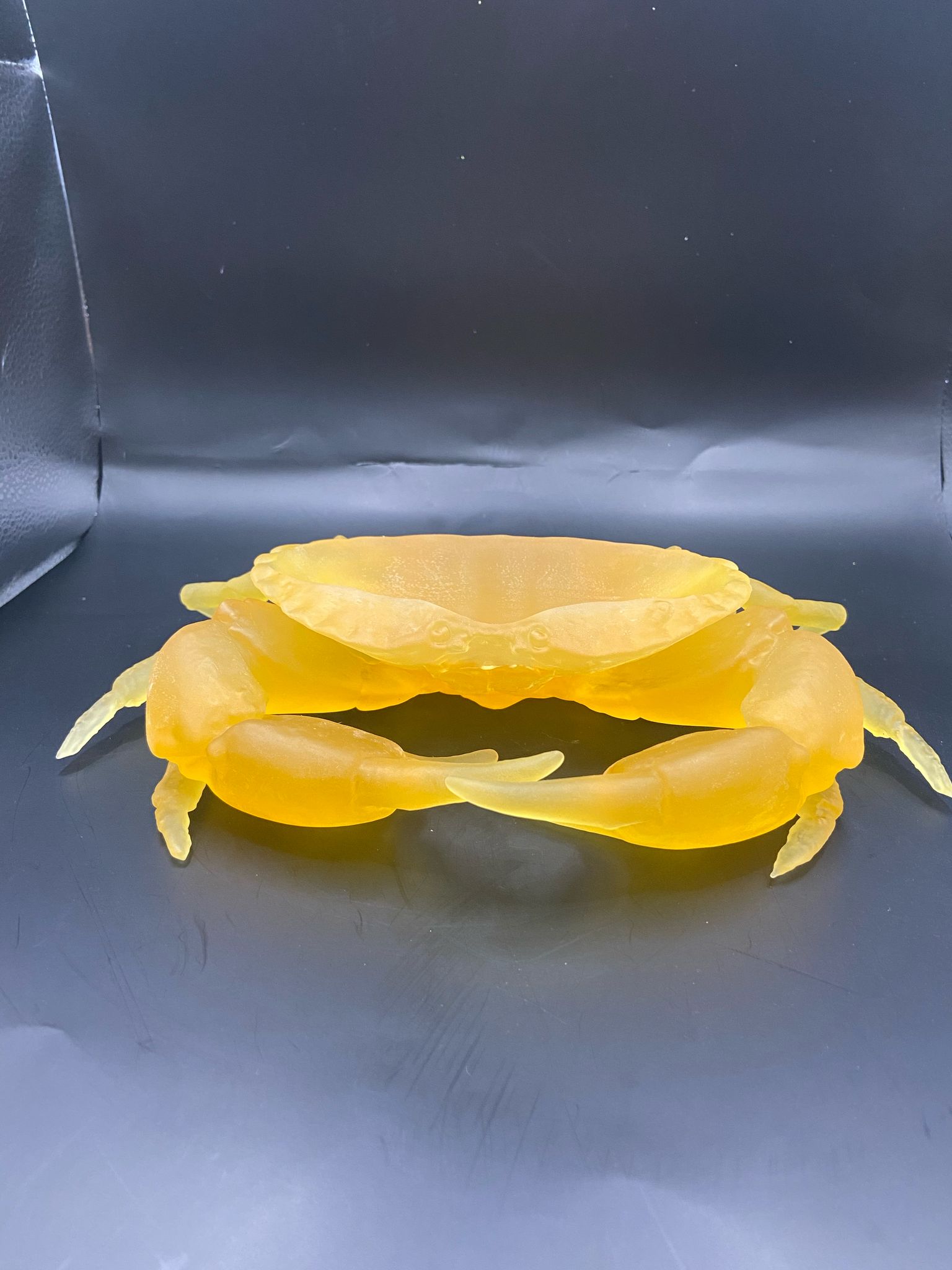

Replik8 then used the CAD file to 3D print the prototype crab in resin, at a high resolution of 16 microns, using a 3D Systems ProJet 2500 Plus MJP 3D printer. Because it was printed in VisiJet M2P- CST Crystal™ resin, the crab dish prototype retained a high level of detail from the original scanned form and was ready to be cast in metal.

Culinary Concepts used the resin prototype to create moulds and cast each part in brass, before welding the legs and claws back onto the body to create the distinctive serving dish.

Reflecting on the project, Emma Jane B. said, “CDG’s team rose to the challenge, expertly mirroring the left and right back legs to ensure proper alignment and that the final printed model would sit evenly. The finished print looked fantastic and was promptly sent to our customer for final approval before being forwarded to our factory in India. There, each leg and claw was separated, and individual moulds were made for casting in brass. The brass pieces were then meticulously welded back onto the main body, resulting in a stunning, lifelike brass crab.

We were thoroughly impressed with CDG’s service. Their professionalism, attention to detail, and quick turnaround — even in the face of last-minute changes — made what could have been a very difficult project feel straightforward. Both the 3D print and the final brass piece were outstanding.”